I called LM engine and ordered a set of there custom pistons with valve reliefs from Michael. I called MMR and asked if there crown was any different than an off the shelf Manley and they said no. There was also a lot less material under the piston. I called Summit and bought a set of Manley platinum. 100' and they held up well until I ran the nitrous lean and it caved in the dome on a few pistons.Guys will often fly cut a small amount out of the pistons with. They told me it was private labeled by Manley. Not all pistons can be fly cut,It always weakens the piston at least a little.How much you can remove depends on how thick that area of the piston is and how strong the piston is.I took a set of TRW smallblock pistons and fly cut them. I saw the new MMR 2500R pistons (rated to 2500hp) and gave them a call. They held up great but I was looking to save a few bucks this time around. 30 over from going lean on the dyno with a 100 shot. The reason I'm replacing pistons is I had to go.

#Flycut pistons yourself how to#

Steve's (03Steve) engine building thread in the TToC provides a great primer for how to do it correctly. To do this checking you will need to use a checking spring and dial indicator among other things. FWIW it is just the opposite for the exhaust. Record the measurements that you get in the area you are wanting to cut. Walk your piston in between the indicator and the punch. Make sure every thing is solid and repeats '0' when cycled.

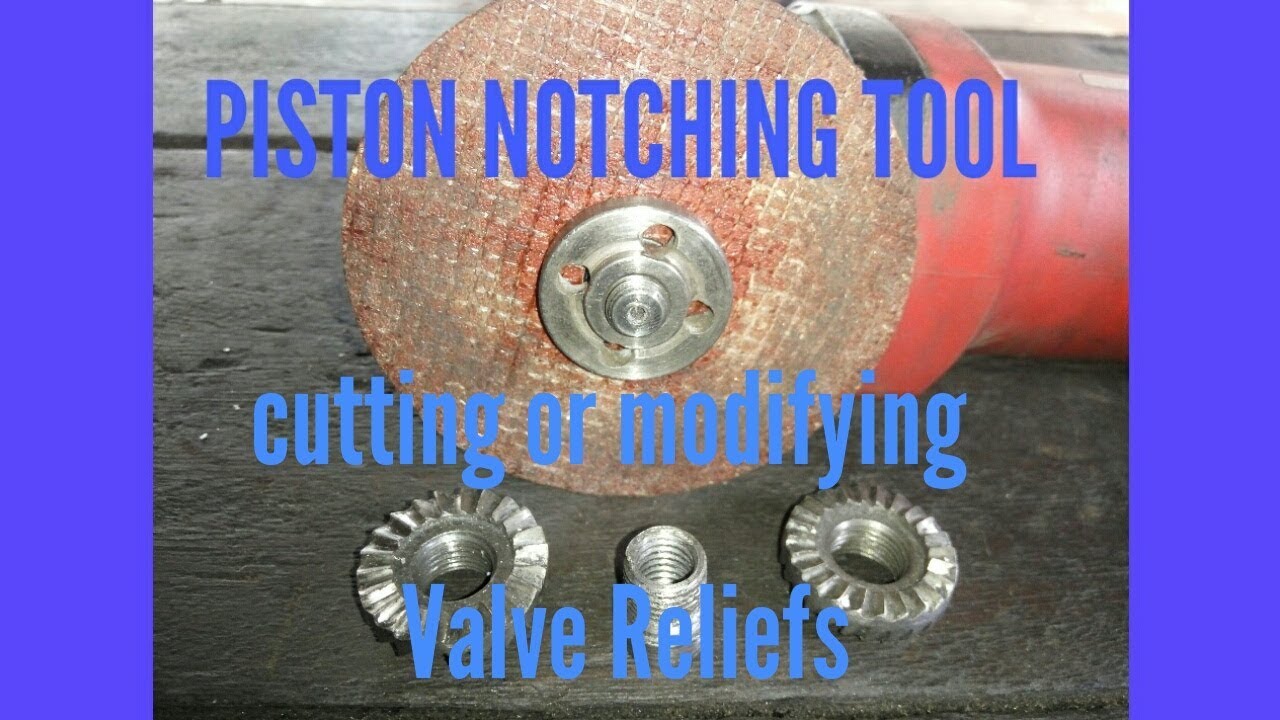

The cam in the case of the intake actually opens the intake valve faster than the piston moves down the cylinder. Position the indicator so that the tip touches the tip of the punch. The collision occurs not because the piston hits the valve but because the intake valve hits the piston - a subtle but important distinction. As Steve has already pointed out that point and its actual clearance will change as you move the cam phasing, relative to the crank, around.Īlthough we call it a piston to valve collision it is actually a valve to piston collision. You will need to check PTV clearance every degree of crank rotation from TDC past the point of closest clearance. As Michael and Tony have already pointed out, your pistons are skinny in the crown dept and not candidates for fly-cutting to achieve proper PTV clearance. There is always a danger involved in using someone else's experience and then firing your engine w/o checking and setting your own PTV clearance. you can get there, but I doubt many of the 520 RWHP cars can troll along in 1st gear at 1000 rpm in stop and go traffic. You can do a nice job yourself with a steady hand and a die grinder and assorted bits, but you will have a tough time being consistant. (chatter marks and whatnot) The best method is a qualified machine shop. It is prudent as the engine builder to actually check your engine's PTV yourself. With some head work, a healthy cam, FAST intake, flycut pistons, etc. I've had to remachine pistons that were originally done with the Isky tool, it doesn't do a very nice job.

0 kommentar(er)

0 kommentar(er)